With the rapid development of the cannabis market, weed stash jars have become an essential part of packaging. They not only serve to store cannabis products but also play a crucial role in enhancing brand image and market recognition. Weed stash jar manufacturers offer a variety of customization services to help brands stand out in the market. However, during the customization process, understanding the cost structure, selecting the right Logo customization techniques, and finding a reliable supplier are the most important concerns for brand owners. This article will explore these aspects in detail, helping brand owners make informed decisions.

Customization Services for Weed Stash Jars

Weed stash jar manufacturers typically provide a range of customization services to meet different brand needs. Customizing storage jars not only enhances the market appeal of the brand but also improves product safety and preservation. Common customization options include:

1. Capacity Customization

Different consumers and usage scenarios have different needs for storage capacity. Customizing the capacity of weed stash jars allows brand owners to target their ideal customer segments:

- Small capacity (5ml-30ml): Ideal for personal daily use, typically used for small quantities of products.

- Medium capacity (50ml-100ml): Suitable for everyday consumers, common for small-to-medium-sized brands.

- Large capacity (200ml and above): Suitable for wholesalers or long-term storage, often targeted at professional or long-term users.

2. Shape Customization

Shape customization is one of the most creative aspects of weed stash jars. Brand owners can design unique shapes based on their needs, enhancing the product’s visual appeal and helping establish a distinct brand image. Common shapes include round, square, triangle,and diamond-shaped jars, with material options like clear glass, frosted glass, or plastic.

3. Logo Customization

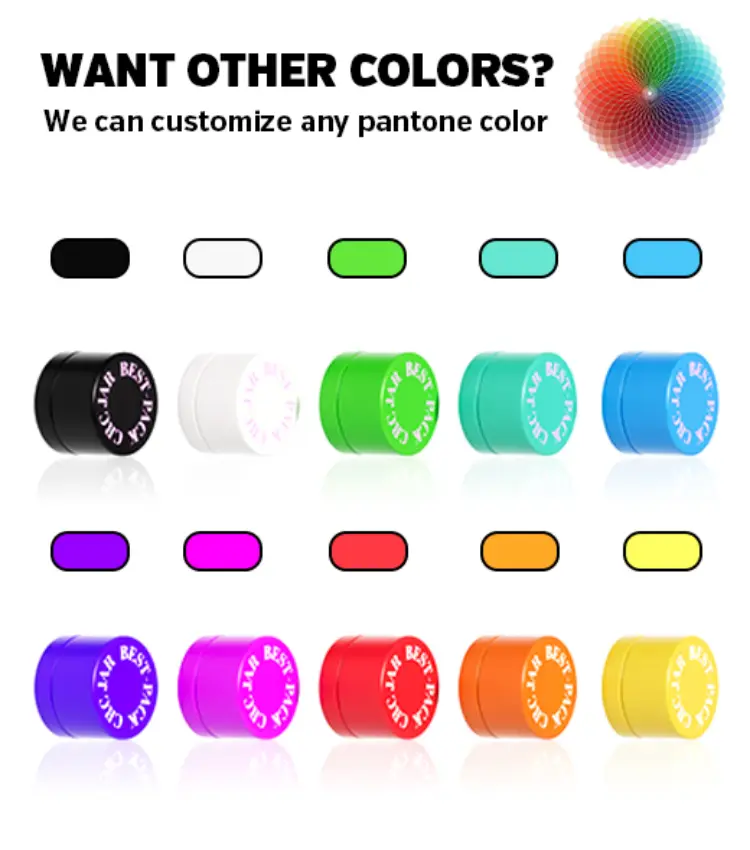

Logo customization can help brand owners enhance their brand image and increase market recognition. Depending on the brand’s needs, there are several common logo customization techniques:

- Spraying

The spray coating technique involves applying paint to the surface of the jar. It is suitable for mass production and offers low cost with vibrant color options, ideal for simple patterns and large color areas. - UV Printing

UV printing uses ultraviolet-cured ink to print fine details and vibrant colors, making it ideal for complex logo designs. It offers high-quality patterns and long-lasting, bright colors, catering to the needs of high-end markets. - Electroplating

Electroplating uses an electrochemical process to coat the surface with a metal layer, adding a luxurious feel. It is perfect for high-end brands, offering metallic luster and enhanced visual effects, and is highly durable, suitable for small batch customizations. - Hot Stamping (Foil Stamping)

Hot stamping transfers a metallic foil film to the surface of the jar using heat and pressure. It is typically used to enhance the visual impact of logos. It’s ideal for intricate designs, offering a premium, luxurious feel to the brand. - Sticker Labels

Sticker labels involve applying pre-printed labels to the surface of the container. It’s the most cost-effective method and is suitable for small batch production. Labels are ideal for brands with a limited budget or those in need of flexible design changes, offering a quick design update.

These different logo customization techniques vary based on the brand’s requirements, design complexity, and budget. Brand owners can choose the most suitable process to enhance their product’s market competitiveness.

We have compiled the advantages, disadvantages, and typical market prices of the five logo manufacturing processes mentioned above into the following table.

| Logo Technique | Price Range (USD/PCs) | Advantages | Disadvantages |

|---|---|---|---|

| Spraying | $0.12–$0.30 | – Low cost, suitable for mass production – Offers a variety of color options | – Durability issues, may fade – Prone to scratches, less durable |

| UV Printing | $0.24–$0.72 | – High-quality prints, fine details – Can print on various surfaces including glass, plastic, etc. | – Best for flat designs, not suitable for complex 3D effects – Surface requirements are high, sensitive to environmental factors |

| Electroplating | $0.60–$1.20 | – Provides metallic luster, adds luxury – Ideal for high-end products | – Higher cost, suitable for small batch production – May experience peeling or scratching, requires extra protection |

| Silk Screen Printing | $0.06–$0.24 | – Low cost, suitable for mass production – Vivid colors, stable prints | – Best for simple designs, not ideal for complex patterns – Detail may suffer, and thickness of coating affects output |

| Sticker Labels | $0.03–$0.12 | – Lowest cost, suitable for small batch production – Can quickly apply and update designs | – Durability issues, prone to wear and fading – Sensitive to environmental factors, may peel or deform |

Cost Structure of Weed Stash Jars

When customizing weed stash jars, understanding the cost structure is crucial for brand owners. Below are the main components of the cost of weed stash jars to help brand owners better control production costs.

1. Raw Material Cost

The materials used for weed stash jars include glass, ceramic, plastic, and other types. The cost of each material varies, and eco-friendly glass or UV-resistant glass tends to be more expensive. Therefore, the choice of raw materials directly affects the overall cost of production.

2. Manufacturing Process Cost

The choice of manufacturing process also impacts costs. For example, techniques such as UV printing, electroplating, and hot stamping require specialized equipment and higher technical expertise, making them more expensive. On the other hand, processes like spraying and sticker labels are more cost-effective and suitable for large-scale production.

3. Custom Design Cost

Logo design, jar shape design, and other custom features generate additional costs. Brand owners can choose to design in-house or hire professional designers. The complexity of the design will directly affect the cost of design.

4. Packaging and Logistics Cost

Packaging methods (such as eco-friendly packaging or high-quality cartons) and transportation costs are significant components of the total cost of weed stash jars. For large orders, transportation and packaging costs can make up a significant portion of the total cost.

How to Choose the Right Logo Customization Technique Based on Budget

When selecting a logo customization technique, brand owners should make informed choices based on their budget and market positioning. Here are the appropriate techniques for different scenarios:

1. For Brands with a Tight Budget

If the brand has a tight budget, spraying and sticker labels are more cost-effective options. Sticker labels are particularly suitable for temporary or small batch production but may have limited durability, making them ideal for short-term use.

2. For Brands Focused on a High-End Image

For brands targeting the high-end market, electroplating and hot stamping offer luxurious, refined visual effects, ideal for conveying a high-end brand image. These techniques add metallic shine and premium aesthetics to the weed stash jar.

3. For Creative and Personalized Brands

UV printing and spraying are suitable for creative and personalized brands, especially UV printing, which offers fine detail and complex designs, ideal for intricate logos and creative patterns.

How to Choose the Right Supplier

Choosing a reliable weed stash jar supplier is essential for ensuring product quality and meeting delivery deadlines. Here are factors to consider when selecting a supplier:

1. Quality Control and Certification

Choose a supplier with a strong quality control system to ensure consistent and reliable product quality. You can request relevant quality certifications, such as ISO9001, to ensure their manufacturing processes meet high-quality standards.

2. Production Capacity and Lead Time

A supplier’s production capacity directly affects lead time, especially for large orders. It’s essential to know the supplier’s production cycle to ensure that they can deliver on time and avoid delays in getting products to market.

3. Customization Capabilities

A qualified supplier should be able to provide flexible customization services based on brand needs. Whether it’s capacity customization, shape customization, or logo customization, the supplier should offer a variety of options to meet different brand demands.

4. Transparent Pricing and Cost Control

Choose a supplier with a transparent pricing system to avoid hidden fees later. A good supplier will help brand owners control costs by optimizing the production process and providing cost-saving solutions.

5. Reputation and Customer Feedback

Look at feedback from other customers to understand the supplier’s service quality and product reputation. Reviews and customer testimonials provide insights into the supplier’s reliability and problem-solving ability, which is key for maintaining a long-term, stable relationship.

Conclusion

Choosing the right customization technique and supplier for weed stash jars can help brands stand out in the market. By understanding logo customization techniques, cost structure, and supplier selection, brand owners can better control production costs while ensuring product quality. Whether it’s through unique shape designs, customized capacity, or various logo customization techniques, the customization of weed stash jars can effectively enhance brand image and market competitiveness.

With proper cost control and innovative design, brand owners can ensure product quality while optimizing overall costs and enhancing brand value.Our easyjars produce glass jar for more than 10 years,we have valume range from 3-1000ml,and more than 5 logo process options,price range is 0.15-0.4 usd/PCs,you can feel free to contact us for latest catalog and quote of weed container.