Choosing the right weed jars bulk manufacturer is a critical decision for cannabis brands seeking stable supply, consistent quality, and controllable packaging costs. A professional bulk manufacturer directly impacts unit pricing, branding execution, lead time, and long-term scalability.

What Defines a Professional Weed Jars Bulk Manufacturer

A qualified weed jars bulk manufacturer is more than a glass supplier. It is a production partner capable of managing materials, tooling, quality control, and volume consistency.

Core capabilities include:

- Bulk glass jar manufacturing capacity

- Consistent mold and dimensional control

- Stable lid and sealing system supply

- Logo and labeling integration

- Cost transparency for large orders

A reliable weed jars bulk manufacturer supports growth without frequent supplier changes.

Manufacturing Capabilities That Affect Bulk Pricing

The production structure of a weed jars bulk manufacturer has a direct influence on cost efficiency and delivery reliability.

In-House vs Outsourced Production

In-house manufacturing reduces variability in weed jars bulk cost by controlling:

- Glass forming

- Annealing and inspection

- Lid fitting and assembly

Manufacturers relying heavily on outsourcing may offer lower entry pricing but higher long-term cost instability.

Production Volume and Scalability

A true weed jars bulk manufacturer should support:

- 5,000 to 100,000+ units per order

- Stable pricing across repeat runs

- Consistent color, thickness, and fit

Scalability ensures bulk pricing improves as volume increases.

Glass Materials Used by Weed Jars Bulk Manufacturers

Glass remains the primary material used by professional weed jars bulk manufacturers due to safety, durability, and compliance advantages.

Standard Clear Glass

Clear flint glass is the most common material due to:

- Neutral chemical properties

- High visual clarity

- Stable bulk pricing

It delivers the best balance between performance and cost control.

Colored and Specialty Glass

Amber, frosted, and UV-blocking glass options increase production cost but add value.

Cost impact:

- +10% to +30% vs clear glass

These materials are often selected by brands focused on shelf differentiation.

Closure Systems and Compliance Manufacturing

A weed jars bulk manufacturer must support compliant closure systems.

Common options include:

- Child-resistant screw lids

- Vacuum or pop-seal lids

- Tamper-evident structures

Lid sourcing consistency is critical, as closure issues are a common failure point in bulk packaging supply chains.

Logo, Label, and Branding Capabilities

Brand execution is a core service offered by modern weed jars bulk manufacturers.

Label Application

- Lowest setup cost

- Flexible for multiple SKUs

- Ideal for early-stage brands

Labels help control cost during product testing.

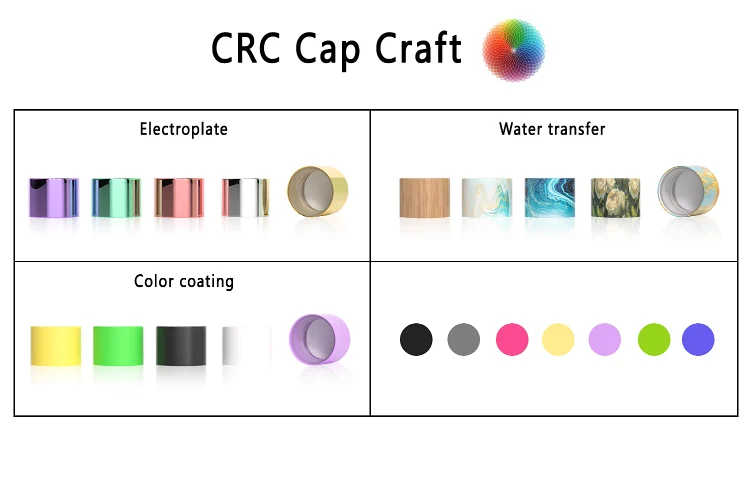

Transfer and Direct Printing

Heat transfer and screen printing provide:

- Higher durability

- Cleaner appearance

- Better long-term cost efficiency

These methods are common once volume stabilizes.

Laser Engraved Logos

Laser engraving is used for premium positioning.

Benefits:

- Permanent branding

- No ink or chemical use

- Minimal wear over time

This option slightly increases cost but improves brand trust and perceived value.

Cost Structure from a Weed Jars Bulk Manufacturer

Understanding pricing logic helps brands plan inventory and margins.

Typical Bulk Price Ranges

- Standard glass jar + CR lid: USD 0.25–0.55

- Printed or colored glass jar: USD 0.35–0.80

- Premium glass + specialty lid: USD 0.55–1.20

Prices decrease significantly at higher order volumes.

Sample vs Bulk Manufacturing Cost

- Samples: USD 2.50–5.00 per unit

- Small batches (500–2,000): USD 0.80–1.60

- Bulk orders (5,000+): Lowest unit cost

Samples validate quality but do not represent true bulk pricing.

How to Choose the Right Weed Jars Bulk Manufacturer

Selecting the right weed jars bulk manufacturer requires evaluating more than price.

Key evaluation criteria:

- Manufacturing experience with cannabis packaging

- Quality control documentation

- Ability to scale production

- Clear communication and lead times

- Transparent pricing structure

A strong manufacturer reduces long-term risk and operational friction.

Manufacturing Details to Confirm Before Production

Before placing a bulk order, confirm:

- Glass thickness tolerance

- Lid compatibility and testing

- Logo durability method

- Packaging and pallet standards

- Defect handling policy

These details prevent costly rework and delays.

Long-Term Cost Optimization with the Right Manufacturer

A strategic weed jars bulk manufacturer helps brands:

- Consolidate SKUs

- Standardize jar sizes

- Reduce tooling duplication

- Improve reorder pricing

Over time, this can reduce total packaging cost by 20%–35%.

Final Thoughts on Choosing a Weed Jars Bulk Manufacturer

A dependable weed jars bulk manufacturer is essential for brand growth, cost stability, and supply reliability. From material control to branding execution, the right partner supports both short-term launches and long-term scale.

If you are searching for a professional weed jars bulk manufacturer with scalable production, customization flexibility, and transparent pricing, Easyjars provides full-service glass jar manufacturing solutions. Contact Easyjars to discuss bulk production options, branding methods, and tailored pricing for your cannabis packaging needs.