In the cannabis industry, the right packaging is essential for both product protection and regulatory compliance. A THC container refers to the packaging used to store and preserve cannabis products, specifically those containing tetrahydrocannabinol (THC). These containers are designed to keep the product fresh, secure, and compliant with industry regulations. If you’re in the cannabis business, understanding the requirements for THC containers is crucial to ensure your products are safely packaged and legally distributed. This guide will explore the types of THC containers, their key requirements, and what to look for in a reliable THC container manufacturer.

What is a THC Container?

A THC container is a specialized type of packaging designed to hold cannabis products that contain THC, the psychoactive compound in cannabis. These containers are typically used to store cannabis flowers, concentrates, edibles, tinctures, or vape cartridges. The primary purpose of a THC container is to preserve the potency, flavor, and freshness of the product while also meeting legal requirements.

Key Requirements for THC Containers

1. Child-Resistant Features

One of the most crucial requirements for THC containers is that they must be child-resistant. Since cannabis is a regulated substance, many regions require packaging to have safety mechanisms that prevent access by children. These features can include screw-on lids, snap closures, or push-and-turn mechanisms. Child-resistant packaging ensures the safety of cannabis products in households with children.

2. Airtight Seal for Freshness

Cannabis products, especially flowers and concentrates, are highly sensitive to air, light, and moisture. Airtight seals are essential to keep products fresh and prevent the degradation of THC and terpenes. A proper seal ensures that the container keeps out excess moisture or air, preserving the potency and quality of the product.

3. UV Protection

UV protection is vital for THC containers that store cannabis flower, as exposure to sunlight can degrade THC, causing it to lose potency. High-quality containers are often made from UV-resistant materials to shield the product from harmful rays and maintain its integrity. This is especially important for products meant for long-term storage.

4. Compliance with Labeling Regulations

Many regions have strict regulations about what information must be displayed on cannabis packaging. THC containers must comply with these regulations by providing clear labeling, which may include:

- THC content

- Dosage information

- Warnings (such as “keep out of reach of children” or “may cause drowsiness”)

- Ingredient list (for edibles or concentrates)

- Expiration dates

Ensure that the THC container manufacturer can accommodate the necessary labels and that their packaging meets these legal requirements.

5. Durability and Safety

Cannabis packaging should be made of materials that protect the product from physical damage. Durability is a key feature of THC containers, as the packaging needs to withstand handling during transportation, retail display, and consumer use. For cannabis concentrates, jars need to be strong enough to avoid cracking or breaking under pressure.

Common Types of THC Containers

1. THC Jars

THC jars are one of the most popular types of cannabis packaging. These containers are often made from glass or plastic and come in a variety of sizes, typically ranging from small 1g jars to larger 10g or 30g containers. Glass jars are commonly used for premium products due to their elegant appearance and ability to preserve product freshness.

2. THC Vials and Bottles

For liquids such as tinctures or vape cartridges, THC vials and bottles are commonly used. These containers are usually made from glass or plastic and are designed to hold small amounts of liquid, often ranging from 1ml to 30ml. Bottles typically feature child-resistant caps for added security.

3. THC Tubes

THC tubes are often used for pre-rolls and are generally made from plastic or cardboard. These containers are lightweight, easy to transport, and come in various sizes. Pre-rolls need proper protection to avoid breaking, and these tubes offer a secure way to store and protect them.

4. THC Mylar Bags

Mylar bags are flexible, airtight containers commonly used for storing cannabis flower. These bags are usually made from a combination of metalized film and plastic, offering excellent protection against moisture, air, and light. Many Mylar bags are child-resistant and can be customized with vibrant designs and logos.

Key Considerations When Choosing a THC Container Manufacturer

1. Material Selection

When selecting a THC container manufacturer, consider the material they offer. Common materials include:

- Glass: Known for its premium feel and UV-protective properties, glass is often used for high-end cannabis products.

- Plastic: Lightweight, durable, and cost-effective, plastic is a popular choice for many types of cannabis packaging.

- Eco-Friendly Materials: As the demand for sustainable packaging rises, many manufacturers offer containers made from recycled or biodegradable materials, which appeal to environmentally conscious consumers.

2. Customization Options

Customization is key to standing out in the competitive cannabis market. A good THC container manufacturer will offer various customization options, such as:

- Custom Labels: Add your brand’s logo, strain information, and safety warnings.

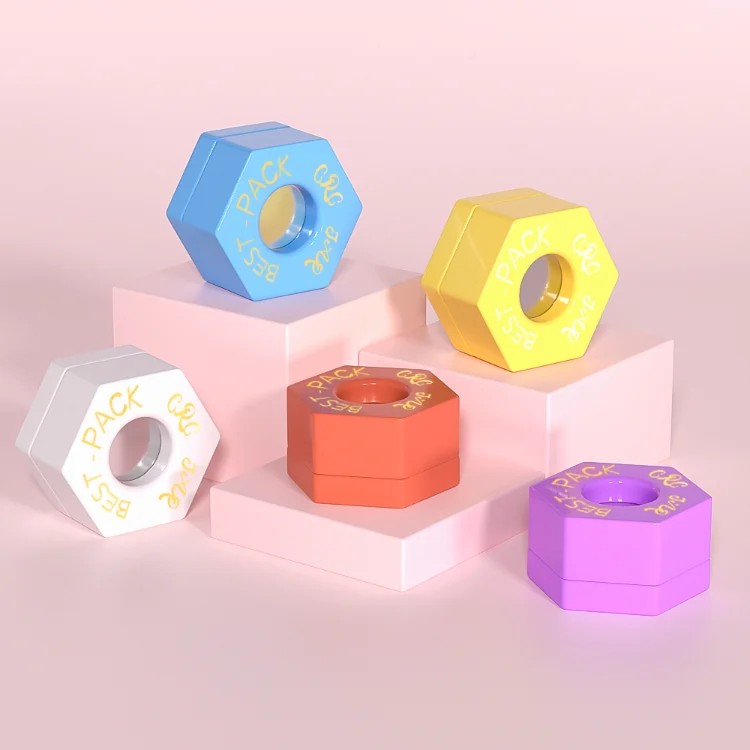

- Color Choices: Choose from a range of colors for the container and lid to match your branding.

- Unique Shapes and Sizes: Stand out by offering packaging in unique shapes or sizes that cater to your target market.

3. Compliance and Regulatory Knowledge

It’s crucial to partner with a THC container manufacturer who is knowledgeable about the cannabis industry’s regulations. Ensure that they are familiar with the legal requirements in your region and can provide compliant packaging with child-resistant features, proper labeling, and any other necessary safety protocols.

4. Lead Time and Minimum Order Quantities (MOQs)

Discuss the supplier’s lead time and MOQs before placing an order. Some manufacturers may have high MOQs, which could be a challenge for smaller cannabis businesses. Understanding the time it takes to produce and deliver the containers is vital for managing your product inventory effectively.

Conclusion: Choosing the Right THC Container Manufacturer

In the cannabis industry, choosing the right THC container manufacturer is essential to ensure your products are safely stored, compliant with regulations, and reflective of your brand’s identity. At EasyJars, we offer a wide range of customizable, child-resistant with pop vac lid design options as picture, and eco-friendly THC containers that help preserve your product’s quality while enhancing its visual appeal. Contact us today for more information and a competitive quote on our high-quality cannabis packaging solutions.