In today’s highly competitive cannabis market, packaging is no longer just functional—it is a key part of brand identity and regulatory compliance. Choosing the right custom pre roll tubes manufacturer can directly influence product quality, shelf appeal, and customer trust. From material selection to child-resistant closures and branding, manufacturers play a central role in how pre-roll products are presented and protected.

This guide explains what to expect from a professional custom pre roll tubes manufacturer, the available materials and design options, pricing factors, and how brands can select the right long-term partner.

What Is a Custom Pre Roll Tubes Manufacturer?

A custom pre roll tubes manufacturer specializes in producing tailored packaging solutions designed specifically for pre-rolled cannabis products. Unlike generic packaging suppliers, these manufacturers understand the functional and regulatory needs of cannabis brands.

They typically support:

- Custom sizing and dimensions

- Glass and plastic pre roll tube options

- Child-resistant and airtight closures

- Branding and logo decoration

- Domestic and international compliance requirements

Working directly with a custom manufacturer gives brands better control over quality, cost, and design consistency.

Why Brands Work with a Custom Pre Roll Tubes Manufacturer

Stronger Brand Differentiation

Retail shelves are crowded. A reliable custom pre roll tubes manufacturer helps brands stand out through:

- Unique colors and finishes

- Custom logos and graphics

- Premium materials that elevate perceived value

Custom packaging reinforces brand recognition and supports premium pricing strategies.

Compliance and Market Readiness

Regulations vary across regions. Experienced manufacturers understand:

- Child-resistant packaging standards

- Label-friendly tube designs

- Market-specific size and closure requirements

A knowledgeable custom pre roll tubes manufacturer reduces compliance risk and saves time during product launches.

Materials Offered by a Custom Pre Roll Tubes Manufacturer

Glass Custom Pre Roll Tubes

Glass is widely considered a premium packaging choice.

Advantages include:

- Excellent odor resistance

- Chemical stability and non-reactive surface

- Clean, high-end appearance

Many manufacturers offer borosilicate or soda-lime glass, depending on durability and cost targets.

Plastic Custom Pre Roll Tubes

Plastic tubes remain popular for high-volume programs.

Benefits include:

- Lightweight and impact-resistant

- Cost-efficient for large orders

- Easy integration with child-resistant caps

A flexible custom pre roll tubes manufacturer often offers both materials to meet different brand needs.

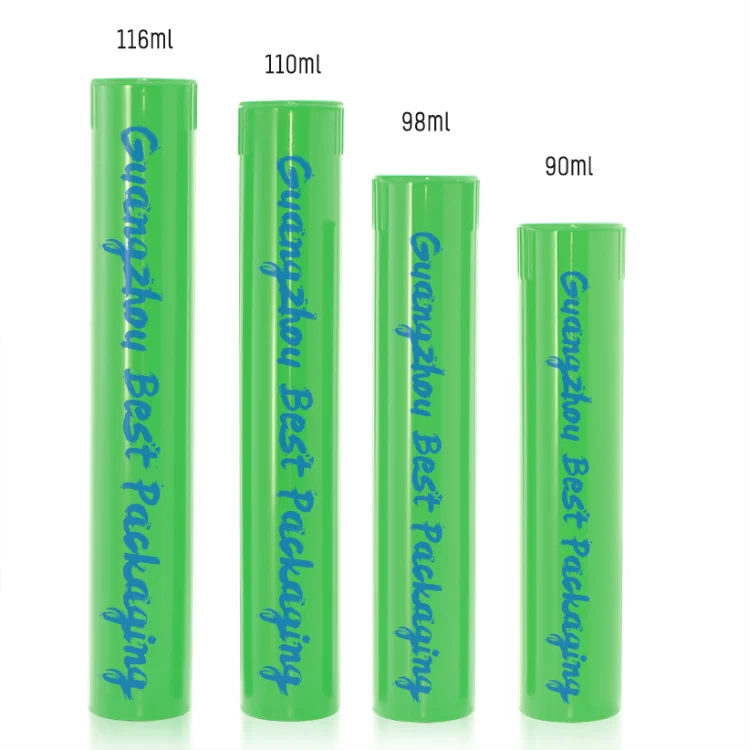

Size and Dimensional Customization

Standard and Custom Lengths

A professional custom pre roll tubes manufacturer provides multiple length options to fit:

- Standard joints

- King-size cones

- Infused or oversized pre-rolls

Correct sizing improves product stability and reduces internal movement during transport.

Diameter and Wall Thickness

Beyond length, tube diameter and glass or plastic thickness affect durability and user experience. Fit testing is an important step before mass production.

Closure and Cap Systems

Child-Resistant Pre Roll Tubes

Child-resistant pre roll tubes are required in many regulated markets. Common CR mechanisms include:

- Push-and-turn caps

- Squeeze-and-open designs

- Pop vac lid designs

An experienced custom pre roll tubes manufacturer can provide tested CR solutions compatible with your target market.

Airtight and Smell-Proof Closures

Odor control is a major consumer concern. Airtight pre roll tubes:

- Help preserve freshness and terpenes

- Reduce smell leakage during storage and transport

Cap liner quality and tube-neck precision are critical for airtight performance.

Branding and Decoration Options

Logo and Printing Techniques

Custom branding options typically include:

- Screen printing

- UV digital printing

- Frosted or etched logos

- Hot stamping or metallic finishes

Each method varies in durability, cost, and appearance. A professional custom pre roll tubes manufacturer will recommend the best option based on usage and budget.

Color and Surface Finishes

Manufacturers may offer:

- Clear, tinted, or solid-color tubes

- Matte or glossy finishes

- Gradient or spray coating effects

Surface treatment also affects label adhesion and long-term wear.

Manufacturing Process and Quality Control

A reliable custom pre roll tubes manufacturer follows strict production and inspection standards, including:

- Dimensional accuracy checks

- Visual inspection for defects

- Cap fit and torque testing

- Drop and stress testing

Consistent quality control reduces breakage, returns, and customer complaints.

MOQ, Pricing, and Cost Factors

What Affects Pricing?

The cost of working with a custom pre roll tubes manufacturer depends on:

- Material selection (glass or plastic)

- Tube size and thickness

- Closure type (standard or child-resistant)

- Printing method and color complexity

- Order volume

Higher volumes typically lower per-unit cost, especially for fully customized designs.

most of the pre roll tube cost 0.2-1 usd/pcs,but our Easyjars factory cost 0.02-0.3 usd per PCs.

Typical MOQ Expectations

MOQs vary by manufacturer and customization level. Simple designs require lower minimums, while unique molds or CR lids may require higher starting quantities.

Lead Time and Logistics Considerations

Production Timelines

Custom projects usually follow this timeline:

- Design confirmation and sampling

- Sample approval

- Mass production

- Packaging and shipment

Clear communication with your custom pre roll tubes manufacturer helps prevent delays.

Shipping and Packaging Safety

Proper export packaging—such as reinforced cartons and internal dividers—is especially important for glass pre roll tubes.

How to Choose the Right Custom Pre Roll Tubes Manufacturer

When evaluating potential partners, consider:

- Cannabis packaging experience

- Range of customization options

- In-house quality control capabilities

- Transparency on pricing and MOQs

- Responsive communication and support

A long-term manufacturing partner provides more value than short-term price advantages.

Sustainability Trends in Pre Roll Tube Manufacturing

Many brands now prioritize eco-conscious packaging. A forward-looking custom pre roll tubes manufacturer may offer:

- Recyclable glass materials

- Reduced plastic use

- Reusable or refillable tube designs

Sustainability adds brand value without compromising performance.

Conclusion

Working with the right custom pre roll tubes manufacturer helps cannabis brands achieve consistent quality, visual differentiation, and regulatory confidence. By understanding materials, closures, customization options, and sourcing factors, brands can make informed packaging decisions that support growth and long-term success.EasyJar supports cannabis brands, wholesalers, and packaging distributors with long-term, stable supply solutions.please feel free to contact with us for more details or get quote now.