Selecting the right cannabis storage jars manufacturer is a strategic decision that directly affects product freshness, regulatory compliance, brand image, and long-term cost efficiency.

What a Cannabis Storage Jars Manufacturer Does

A professional cannabis jars manufacturer designs, produces, and customizes containers specifically engineered for cannabis flower, pre-rolls, concentrates, and infused products. Unlike general packaging suppliers, a specialized cannabis jars manufacturer understands odor control, airtight sealing, UV protection, child-resistant standards, and branding consistency.

Modern cannabis brands rely on a cannabis storage jars manufacturer not only for production but also for design validation, prototyping, labeling, quality assurance, and scalable supply.

Material Options Offered by a Cannabis Storage Jars Manufacturer

Material selection is one of the most critical decisions when working with a cannabis jars manufacturer, as it impacts shelf life, cost, and consumer perception.

Glass Cannabis Storage Jars

Glass is the most widely used option from a premium cannabis jars manufacturer.

Key advantages:

- Non-reactive and terpene-safe

- Superior airtight performance

- Compatible with UV-blocking coatings

- High-end brand positioning

Common variants:

- Clear glass jars

- Frosted cannabis jars

- Amber or black UV glass jars

Glass is ideal for premium flower and long-term storage.

Plastic Cannabis Storage Jars

Plastic jars are commonly supplied by cost-focused cannabis storage jars manufacturers serving large-scale distribution.

Typical materials:

- PP (polypropylene)

- PET

- HDPE

Advantages:

- Lightweight and shatter-resistant

- Lower tooling and unit costs

- Easy integration of child-resistant closures

Plastic cannabis storage jars are widely used for pre-rolls and value-focused brands.

Metal Cannabis Storage Jars

Some specialized cannabis storage jars manufacturers offer aluminum or tin packaging.

Benefits:

- Strong odor containment

- Durable and portable

- Modern, lifestyle-oriented appearance

Metal jars are often used for travel kits, promotional packaging, and limited editions.

Supplier Manufacturing Process: From Design to Production

A professional cannabis storage jars manufacturer follows a structured production workflow to ensure consistency, compliance, and efficiency.

Step 1: Design Drawings and Technical Review

The process begins with 2D or 3D drawings provided by the client or developed by the cannabis storage jars manufacturer. At this stage, manufacturers review:

- Jar dimensions and capacity

- Closure type and sealing mechanism

- Material thickness and tolerance

- Regulatory requirements

Design-for-manufacturing (DFM) feedback is essential to avoid future issues.

Step 2: Prototyping and Sampling

Before mass production, a qualified cannabis storage jars manufacturer produces prototypes or pre-production samples. This stage allows brands to verify:

- Fit and seal performance

- Visual appearance

- Label placement

- Logo accuracy

Sampling reduces risk and shortens the approval cycle.

Step 3: Tooling and Mold Development

For custom shapes or closures, the cannabis storage jars manufacturer creates dedicated molds. Tooling quality directly impacts:

- Dimensional consistency

- Surface finish

- Long-term production stability

Logo Printing, Labeling, and Customization Options

Customization is a core value offered by a professional cannabis storage jars manufacturer.

Logo Decoration Methods

- Screen printing

- UV printing

- Hot stamping

- Laser engraving

Each method offers different durability, cost, and visual effects.

Label Customization

A reliable cannabis storage jars manufacturer supports:

- Pressure-sensitive labels

- Shrink sleeves

- Wrap-around labels

Label material, adhesive type, and ink durability are carefully matched to jar materials.

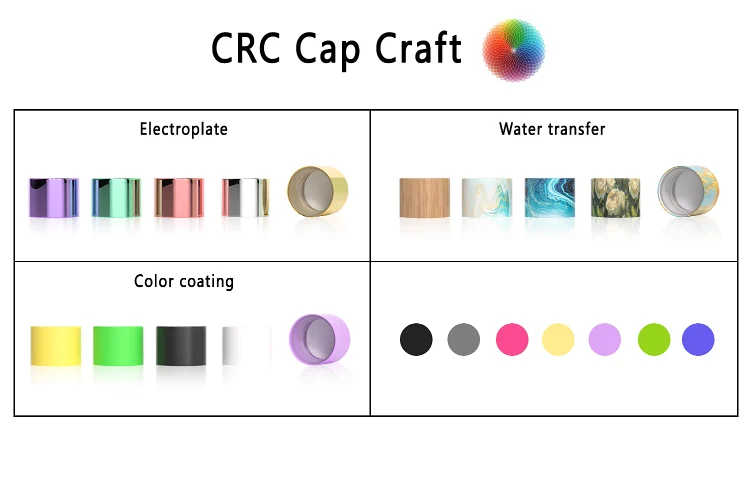

Color and Surface Finishes

- Matte or glossy coatings

- Frosted textures

- Custom color matching

These options help brands stand out in competitive retail environments.

Quality Control in Cannabis Storage Jars Manufacturing

Quality control is a defining factor when evaluating a cannabis storage jars manufacturer.

Core Quality Inspection Areas

- Airtight and leak testing

- Odor containment verification

- Dimensional tolerance checks

- Surface defect inspection

Quality Control Process Stages

A professional cannabis storage jars manufacturer applies QC at:

- Incoming material inspection

- In-process production checks

- Final pre-shipment inspection

Common Quality Control Pitfalls to Avoid

- Inconsistent gasket materials

- Poor thread alignment

- Ink adhesion failures

- Inadequate sampling plans

Working with an experienced cannabis jars manufacturer minimizes these risks.

Cost Ranges and Pricing Factors

Understanding cost structure helps brands plan more effectively with a cannabis storage jars manufacturer.

Key Cost Drivers

- Material type and thickness

- Custom tooling requirements

- Decoration and labeling methods

- Order quantity (MOQ)

- Compliance features

Typical Cost Ranges

- Plastic jars: lowest cost per unit

- Glass jars: mid-range pricing

- Metal jars: higher material and finishing costs

A transparent cannabis storage jars manufacturer provides itemized quotations.

How to Reduce Cost While Maintaining Quality

Cost optimization should never compromise performance. Experienced cannabis storage jars manufacturers help clients reduce cost through:

- Standardized jar shapes with custom decoration

- Optimized wall thickness

- Consolidated labeling processes

- Batch production planning

Early design collaboration with the cannabis storage jars manufacturer is the most effective cost-control strategy.

How to Choose the Right Cannabis Storage Jars Manufacturer

Supplier selection determines long-term success.

Before Cooperation: Supplier Evaluation

When shortlisting a cannabis jars manufacturer, assess:

- Manufacturing experience in cannabis packaging

- Material certifications

- Customization capability

- Communication efficiency

- Sign a Non-Disclosure Agreement (NDA)

During Cooperation: Project Execution

During production, strong cannabis jars manufacturers provide:

- Clear timelines

- Regular progress updates

- Sample confirmation checkpoints

Consistency during this phase builds trust.

After Cooperation: Long-Term Partnership

Post-delivery evaluation should focus on:

- Product consistency across batches

- On-time delivery performance

- After-sales support

- Sign a Non-Disclosure Agreement (NDA)

Reliable cannabis storage jars manufacturers aim for repeat collaboration, not one-time transactions.

Additional Considerations for Global Cannabis Brands

International brands must ensure their cannabis storage jars manufacturer understands:

- Export packaging standards

- Regional compliance differences

- Logistics and lead-time planning

Manufacturers with global experience reduce risk and accelerate market entry.

Final Thoughts and Next Steps

Working with the right cannabis storage jars manufacturer ensures product freshness, regulatory compliance, and a strong brand presence in an increasingly competitive cannabis market. From material selection and custom design to quality control and cost optimization, the manufacturer you choose becomes an extension of your brand.

If you are planning custom cannabis packaging and need expert guidance on materials, production processes, quality assurance, and cost control, EasyJars provides end-to-end support as a professional cannabis jars manufacturer. Contact EasyJars to discuss your project requirements and request detailed pricing information tailored to your brand.