The global cannabis industry continues to expand, and demand for high-quality packaging has made a reliable pre rolled tubes factory more important than ever. Brands rely on durable tubes—especially glass and plastic options—to protect pre-roll freshness, enhance shelf appeal, and meet regulatory requirements. This guide explains the materials, manufacturing processes, costs, and how to choose the right pre rolled tubes manufacturer or pre rolled tubes supplier for your business.

Why Pre-Roll Tubes Are Essential in Modern Cannabis Packaging

Pre-roll tubes serve as one of the most common packaging formats in dispensaries and wholesale cannabis distribution.

Key Functions

- Protect pre-rolls from crushing

- Preserve aroma and terpene profile

- Ensure child-resistant compliance

- Support branding and premium presentation

- Improve transportation durability

These functions drive the consistent demand for a well-equipped pre rolled tubes factory capable of meeting volume, quality, and customization needs.

Two Main Materials Used in Pre-Roll Tubes — Glass vs. Plastic

A professional pre rolled tubes manufacturer typically produces tubes using two primary materials: glass and plastic (polypropylene or PET). Each has its own advantages, applications, and pricing structure.

Glass Pre-Roll Tubes — Premium Quality for High-End Brands

Glass is the preferred material for premium cannabis packaging.

Advantages

- Superior freshness protection: Airtight and non-reactive

- High clarity: Enhances retail presentation

- Odor retention: Maintains terpene aroma

- Reusable & eco-friendly

- with CR lids

Common Glass Types

- Borosilicate glass

- Clear soda-lime glass

- UV-resistant colored glass

- Frosted or matte finish glass

Typical Sizes

98mm / 116mm / 120mm / 140mm

A good pre rolled tubes factory provides all major sizes and lid compatibility options.

Typical Applications

- Premium pre-rolls

- Infused pre-rolls

- Multi-gram pre-rolls

- Promotional cannabis packaging

Price Range

$0.20 – $0.90 per tube depending on size, thickness, and customization.

Plastic Pre-Roll Tubes — Cost-Effective, Lightweight & Flexible

Plastic tubes (usually PP or PET) dominate the affordable market segment.

Advantages

- Low cost

- Shatter-resistant

- Lightweight for shipping

- Available in many colors

- Easy to open and close

- Water-resistant

Typical Plastic Variants

- PP (Polypropylene): Most common

- PET (Polyethylene Terephthalate): Clearer than PP

- Recycled plastics (eco-friendly options)

Applications

- Standard pre-rolls

- Bulk packaging for dispensaries

- Outdoor and seasonal products

- Entry-level cannabis brands

Price Range

$0.05 – $0.25 per tube, making them ideal for high-volume orders.

Plastic tubes allow a pre rolled tubes supplier to serve both budget-conscious brands and large distributors.

Inside a Pre Rolled Tubes Factory — How Production Works

The following steps show how a professional pre rolled tubes factory designs and produces both glass and plastic tubes.

Step 1 — Raw Material Processing

Glass

- Heated to over 1,000°C

- Shaped using rotary molds

- Cooled in annealing furnaces

Plastic

- Polymer pellets melted at 200–260°C

- Molded using injection molding machines

- Quickly cooled and ejected

Step 2 — Tube Forming & Neck Design

The tube neck must fit airtight and CR-compatible lids.

Precision here determines product functionality.

Step 3 — Surface Finishing

Factories may provide:

- Frosting

- UV coating

- Color tinting

- Painted finishes

Step 4 — Custom Branding

A professional pre rolled tubes manufacturer offers:

- Screen printing

- Heat-transfer printing

- Digital printing

- Laser-etched logos

Step 5 — Quality Control

Every batch should be tested for:

- Drop resistance

- Airtightness

- Odor sealing

- Consistent weight

- Child-resistant functionality

Reliable factories maintain strict QC logs.

Factors That Influence Pre Rolled Tubes Price

Whether working with a wholesaler or a direct pre rolled tubes supplier, these elements impact the final cost:

1. Material Type

Glass > PET > PP

Material quality has the biggest effect on unit price.

2. Size & Thickness

Larger and thicker tubes require more raw material.

3. Lid Type

- Standard snap-on lids

- Child-resistant lids (higher cost)

- Metal lids

- Cork lids (premium, aesthetic)

4. Custom Options

Color, printing, engraving, and UV protection all increase cost.

5. Packaging Method

- Bulk carton → cheapest

- Partitioned boxes → medium

- Individual boxes → most expensive

6. Order Quantity

Larger orders significantly reduce individual unit price.

Pricing Comparison — Glass vs Plastic Pre-Roll Tubes

| Tube Material | Standard Price | Premium Price | Key Advantage |

|---|---|---|---|

| Plastic (PP/PET) | $0.05–$0.25 | $0.20–$0.40 | Cheapest, lightweight |

| Glass (Clear/Frosted) | $0.20–$0.60 | $0.50–$0.90 | High-end, reusable |

| UV Glass | $0.30–$0.80 | $0.70–$1.20 | Protects terpenes from light |

| Printed Custom Tubes | $0.30–$0.90 | $1.00–$1.50 | Great branding impact |

Glass offers premium protection and display, whereas plastic delivers the lowest cost per unit.

How to Reduce Pre Rolled Tubes Price

A strong pre rolled tubes manufacturer can help you lower cost by optimizing product selection and production details.

1. Choose Standard Sizes

Avoid expensive custom molds unless necessary.

2. Limit Printing Colors

Single-color printing reduces setup cost.

3. Order in Bulk

10,000+ units usually unlock the best pricing.

4. Choose Standard CR Lids

Custom lids raise tooling and certification expenses.

5. Use Bulk Packaging

Individual packaging increases freight volume and cost.

6. Consider PET Instead of PP

Clearer yet still affordable, PET offers great branding visibility.

What Makes a Reliable Pre Rolled Tubes Factory?

Choosing the right pre-roll packaging partner matters more than choosing the cheapest price.

Key Traits of a Professional Factory

- Large-scale production capacity

- Consistent clarity & material quality

- Child-resistant compliance certifications

- Strong breakage control for glass shipments

- Fast lead times (7–20 days)

- Full customization capabilities

- Experience with both plastic & glass materials

A qualified pre rolled tubes supplier should provide samples, QC documentation, and printed mockups before mass production.

Why Choose Easyjars as Your Pre Rolled Tubes Supplier

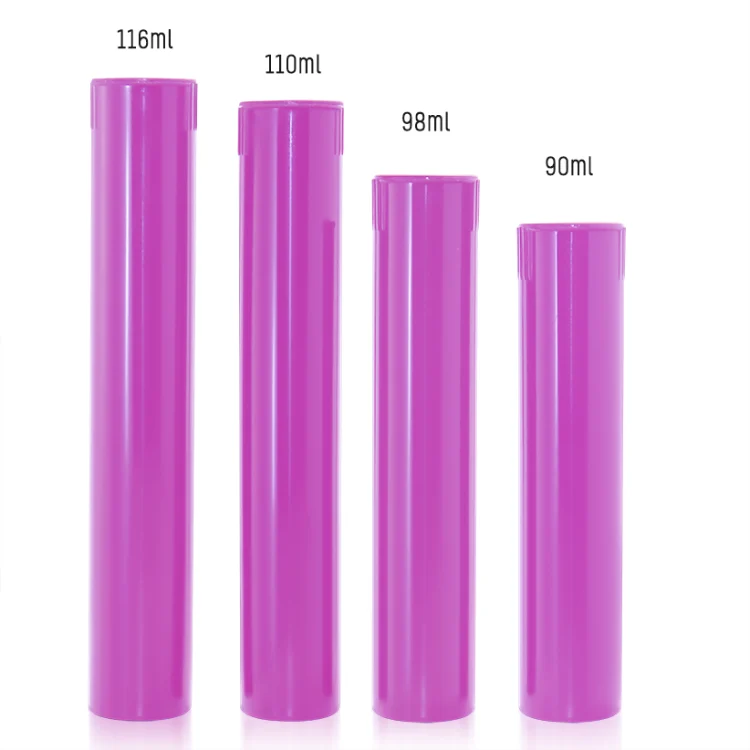

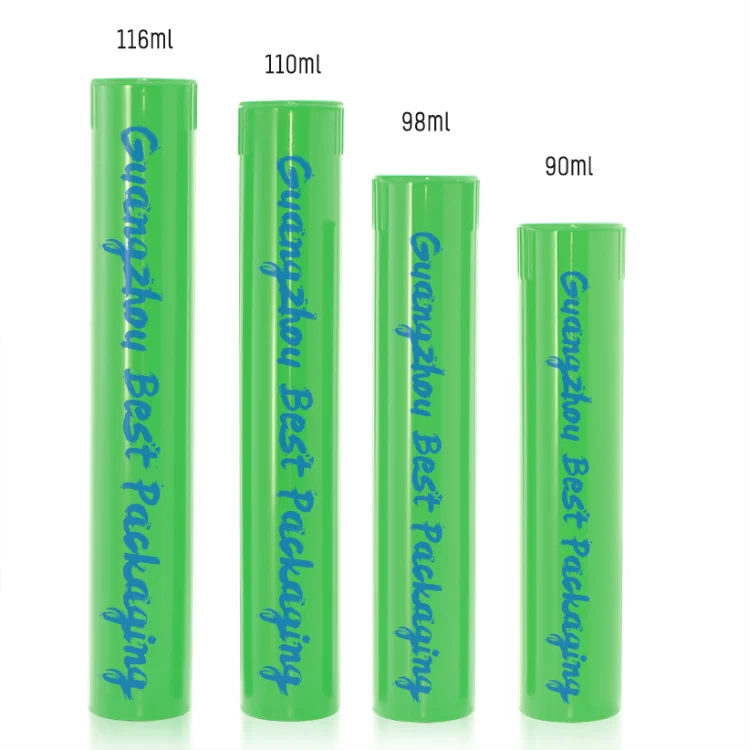

We supply a full range of plastic and glass pre-roll tubes with consistent quality, fast delivery, and competitive pricing. Our production covers all industry-standard sizes — 90mm, 98mm, 110mm, 112mm, 116mm, 120mm, and 125mm — ensuring compatibility with every major pre-roll format on the market.

Our Pricing Advantage

- Plastic pre roll tubes: 0.02–0.05 USD per unit

- Glass pre roll tubes: 0.05–0.15 USD per unit

With strong production capabilities as an experienced pre rolled tubes factory, we also provide:

- Certified child-resistant caps

- High-clarity, durable materials

- Custom printing and color options

- Bulk wholesale pricing for large orders

- Low MOQ support for startup brands

- Protective packaging to minimize breakage during transport

- Pop vacuum cap options

If you would like an accurate quotation for your size, color, volume, or customization requirements, contact us anytime to get the best pre rolled tubes price for your brand.